Tensile fabric structures use high-strength coated fabrics as primary structural elements, requiring rigorous mechanical testing. PVC-coated polyester is most common, providing excellent strength-to-weight ratio for roofs, façades, and freestanding structures. Testing verifies fabric meets structural design assumptions for tensile strength, tear resistance, and long-term performance under environmental loading.

Tensile Fabric Materials and Applications

Architectural fabrics consist of woven base cloth (polyester, glass fiber, or aramid) with polymer coating (PVC, PTFE, silicone). PVC/polyester fabrics dominate temporary and semi-permanent structures. Typical strength ranges from 2000-8000 N/5cm width. Applications include stadium roofs, atrium coverings, canopy structures, tensile façades, and temporary buildings. Fabric acts as structural membrane resisting tension in warp and fill directions.

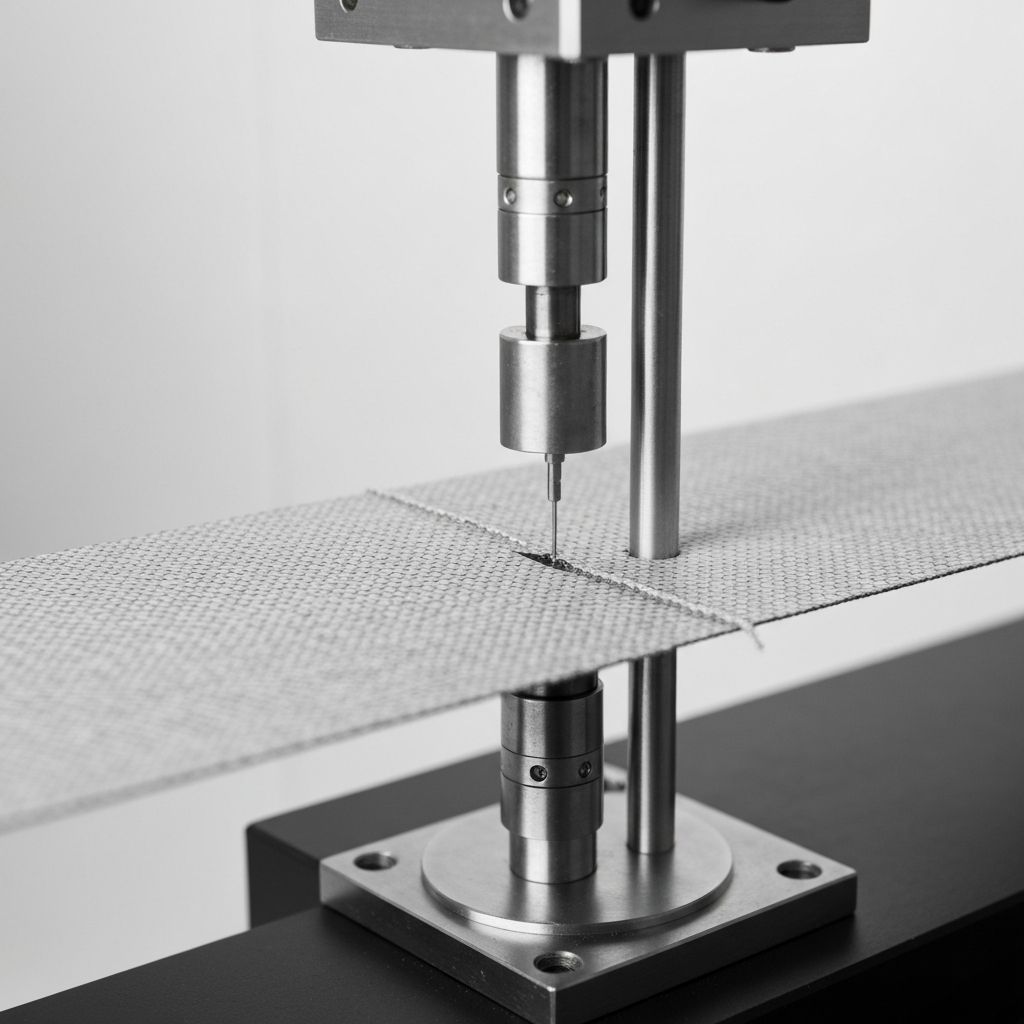

Tensile Strength Testing

Strip tensile testing (EN ISO 1421, ASTM D5035) measures maximum load capacity in warp and fill directions. Specimens 50-200mm wide are gripped and loaded in universal testing machine until rupture. Both breaking strength and elongation at break are recorded. Testing at multiple environmental conditions (temperature, UV exposure) establishes design values with appropriate safety factors.

- Strip method: 50mm wide specimen, 200mm gauge length, 100mm/min loading rate

- Grab method: Alternative for quality control, faster but less precise

- Biaxial testing: Cruciform specimen loaded simultaneously in both directions, most realistic

- Acceptance criteria: Minimum 85-90% of manufacturer's declared strength

- Test frequency: Per production lot and after aging/weathering exposure

Tear Strength Testing

Tear resistance is critical where fabric attaches to structure or penetrations occur. Trouser tear test (EN ISO 4674) uses specimens with pre-cut, with legs pulled in opposite directions. Tongue tear (ASTM D2261) uses single-strap specimen with cut. Trapezoidal tear (ASTM D5587) measures tear propagation under combined tension and tearing forces. Results guide edge detail design and reinforce requirements.

Long-Term Performance and Durability

Fabrics degrade through UV exposure, thermal cycling, flexing, and environmental stress. Accelerated aging testing (EN 13206, ASTM G155) uses Xenon arc lamps to simulate years of UV exposure in weeks. Tensile retention after aging (typically 70-80% strength retention required) indicates service life. Flexural fatigue testing ensures fabric withstands wind-induced fluttering and thermal movement without degradation.

Conclusion

Tensile fabric testing ensures materials meet demanding structural and durability requirements for membrane structures. Our laboratory performs comprehensive fabric testing to international standards. Contact us for tensile fabric materials testing.

Related Testing Services

- UV Resistance Testing

- Seam Strength Testing

- Fire Resistance Testing

- Abrasion Resistance

Applicable Standards

Need This Testing Service?

Our accredited laboratories and field teams provide comprehensive testing services across Europe.

Contact Our Team