UV radiation is the primary environmental factor degrading tensile fabric structures. Prolonged UV exposure breaks polymer chains, causing discoloration, strength loss, and material embrittlement. UV resistance testing using accelerated weathering equipment predicts long-term performance and verifies that fabrics meet specified service life (typically 10-30+ years for architectural applications).

UV Degradation Mechanisms

UV radiation (particularly 290-400nm wavelength) provides energy to break chemical bonds in both base fabric and coating. Polyester yarns absorb UV causing chain scission and strength loss. PVC coatings yellow, crack, and delaminate. Degradation accelerates with heat and moisture. Modern fabrics incorporate UV stabilizers (benzotriazoles, HALS) and pigments (titanium dioxide) that absorb/reflect UV, significantly extending service life.

Accelerated Weathering Testing

EN 13206 and ASTM G155 specify xenon arc lamp weathering. Equipment simulates full spectrum sunlight including UV, visible, and IR radiation with controlled temperature and moisture cycling. Specimens are exposed for periods equivalent to years of outdoor service (e.g., 2000 hours ≈ 5-10 years). Periodic testing measures tensile strength retention, color change, and physical appearance.

- Exposure conditions: Xenon arc lamp at 0.35-0.55 W/m²/nm at 340nm, daylight filter

- Temperature cycling: Typically 65°C black panel temperature, humidity cycles

- Exposure periods: 500, 1000, 2000, 5000+ hours depending on requirements

- Performance criteria: Typically ≥70-80% tensile strength retention after specified exposure

- Color stability: ΔE <4-5 for architectural appearance requirements

Natural Weathering Correlation

Accelerated test results are correlated to natural outdoor exposure through reference materials and geographic exposure sites. Florida and Arizona exposure racks provide maximum UV intensity natural weathering. Correlation factors typically range from 3:1 to 8:1 (accelerated:natural years) depending on fabric composition and exposure intensity. Conservative design uses lower correlation factors and includes safety margins.

Service Life Prediction and Warranties

Manufacturers provide service life predictions based on weathering data, field performance history, and conservative extrapolation. High-quality PVC/polyester fabrics typically offer 15-25 year service life in moderate climates. PTFE-coated glass fiber fabrics exceed 30+ years. Warranty terms typically cover strength retention rather than appearance. Periodic inspection and testing of installed fabrics validates predictions and guides maintenance decisions.

Conclusion

UV resistance testing is essential for predicting long-term performance of tensile fabric structures. Our laboratory performs accelerated weathering testing to international standards with comprehensive reporting. Contact us for fabric durability testing services.

Related Testing Services

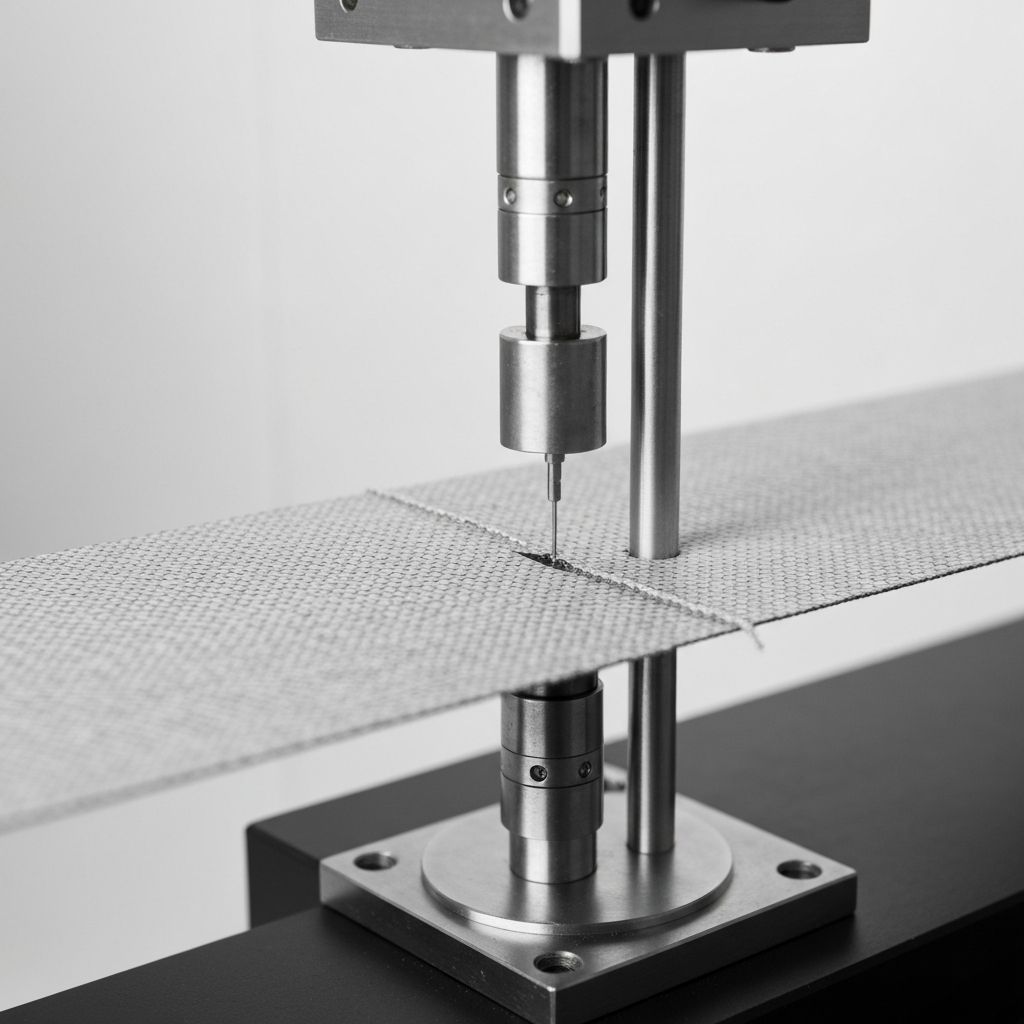

- Tensile Strength Testing

- Color Fastness Testing

- Thermal Aging

- Ozone Resistance

Applicable Standards

Need This Testing Service?

Our accredited laboratories and field teams provide comprehensive testing services across Europe.

Contact Our Team