Seam quality is critical in tensile fabric structures as seams are potential weak points where stress concentrations occur. PVC-coated fabrics are typically joined by thermal welding (hot air, hot wedge, or RF welding) creating fusion bonds. Seam strength must equal or exceed fabric base strength to prevent zipper failures. Systematic testing ensures fabrication quality meets structural design requirements.

Seam Types and Joining Methods

Common seam configurations include lap seams (overlapping fabric sheets welded together), butt seams with backing strip, and keder/rope edge details for attachment to structure. Hot air welding uses 400-600°C air to melt coating surfaces which are pressed together. RF (radio frequency) welding uses electromagnetic energy to heat and fuse thermoplastic coatings. Proper parameters (temperature, pressure, speed) are critical for seam quality.

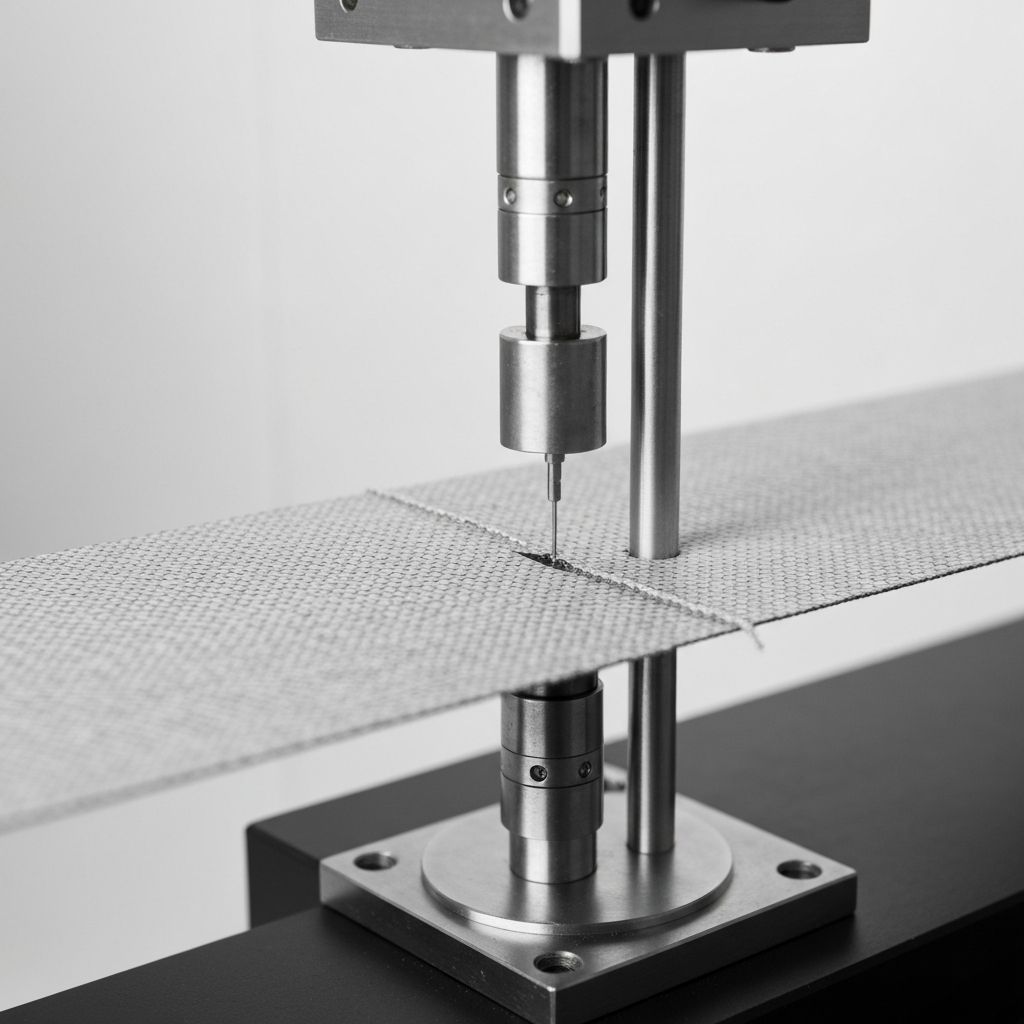

Seam Strength Testing Procedure

Strip tensile testing of seam samples (EN ISO 1421, ASTM D751) measures joint strength parallel to seam line. Specimen is gripped on both sides of seam and loaded until failure. Acceptable failure modes include yarn failure in base fabric adjacent to seam, or fabric tearing away from seam. Unacceptable failures include delamination at weld interface, indicating poor seam quality requiring process adjustment.

- Specimen preparation: 50-100mm wide strips with seam at center, minimum 200mm length

- Test setup: Grips on both sides of seam, load perpendicular to seam line

- Loading rate: 100mm/min standard rate, load to complete failure

- Acceptance: Seam strength ≥85-90% of fabric base strength typically required

- Frequency: Initial qualification testing, then routine quality control samples per production run

Peel Strength Testing

T-peel or 90° peel testing (EN 28510, ASTM D1876) evaluates resistance to peeling forces that separate seam layers. This loading occurs at detail connections and seam terminations. Test specimen is gripped with fabric legs pulled in opposite directions. Peeling resistance is measured as force per width. Consistent peel strength indicates uniform weld quality along seam length.

Quality Control and Troubleshooting

Non-destructive testing includes visual inspection for delaminations, wrinkles, or contamination. Probe testing attempts to separate seam edges with blunt instrument. Destructive peel testing of trial seams before production runs verifies parameters. Common seam defects include inadequate heat (weak weld), excessive heat (degraded material), contamination (dirt, moisture preventing adhesion), and insufficient pressure (incomplete fusion). Process adjustments address specific defects.

Conclusion

Seam testing ensures fabrication quality meets structural design assumptions for tensile fabric structures. Our laboratory performs seam strength and peel testing to international standards. Contact us for fabric seam testing services.

Related Testing Services

- Tensile Fabric Strength Testing

- Peel Adhesion Testing

- Tear Resistance Testing

- Joint Design Testing

Applicable Standards

Need This Testing Service?

Our accredited laboratories and field teams provide comprehensive testing services across Europe.

Contact Our Team