Mortar compression testing verifies that mortar achieves specified strength and that mix proportions are correct. Mortar bonds masonry units and transfers loads between units. Inadequate mortar strength reduces wall capacity and can cause structural failure. Systematic testing ensures consistent mortar quality throughout construction, identifying problems before they affect structural performance.

Mortar Strength Requirements

EN 998-2 classifies mortars by compressive strength: M2.5, M5, M10, M15, M20 (numbers indicate strength in N/mm² at 28 days). General-purpose mortar is typically M5-M10. Structural applications may require M15-M20. Mortar doesn't need to match unit strength - mortar 2-3× weaker than units often performs best, allowing stress redistribution. Specifications balance strength, durability, and workability.

Sample Collection and Molding

Mortar samples are collected from mixer or mortar board, ensuring samples represent material actually used in construction. For quality control, six 100mm cubes are molded from each sample. Cubes are compacted in molds by tamping or vibration. Specimens are cured in molds for 24 hours, then demolded and stored in controlled humidity (90%+ RH) at 20°C until testing.

- Sampling frequency: Daily when large volumes used, or per 100m² of masonry

- Test ages: 7 days and 28 days (3 cubes per age)

- Compaction: Standard energy applied - 15 drops from 40mm or tamping rod

- Curing: Covered to prevent moisture loss initially, then humidity chamber

- Testing: Three cubes tested per age, results averaged

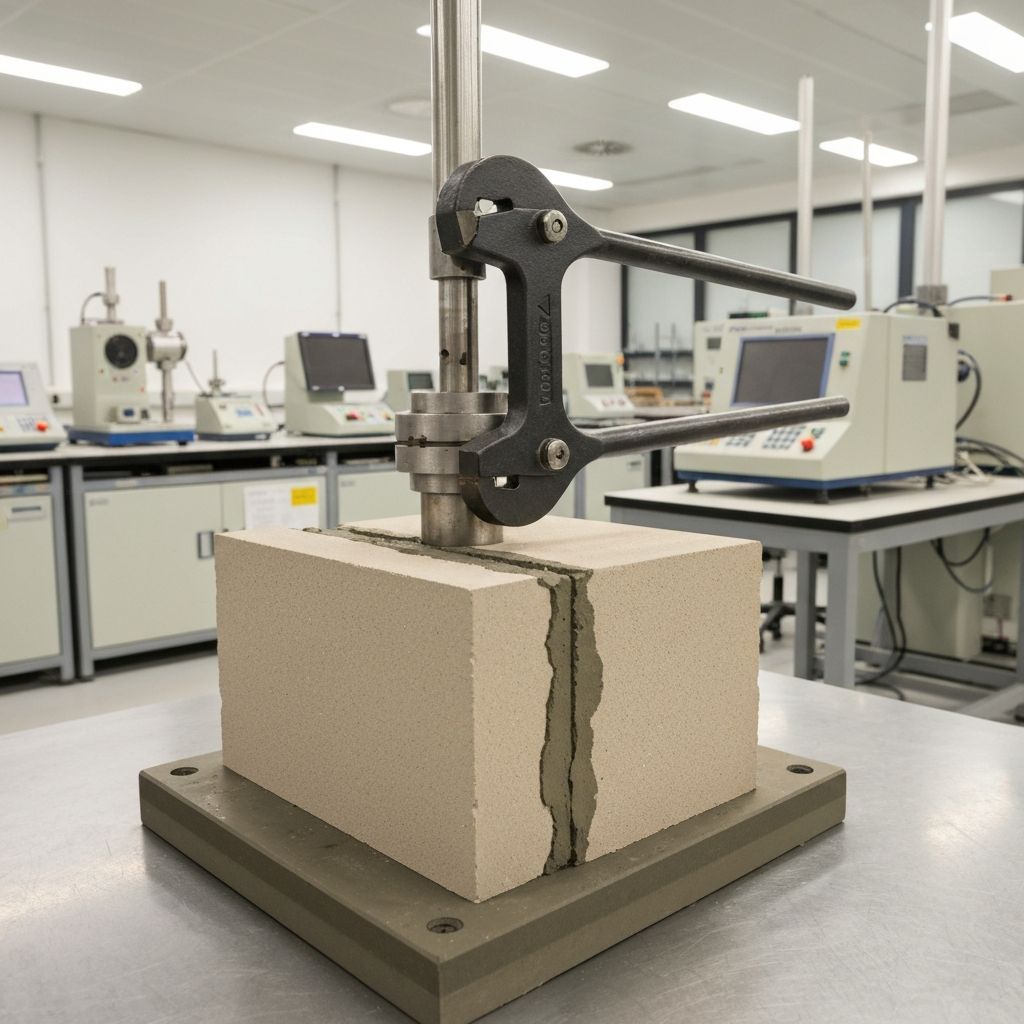

Testing Procedure and Acceptance

Cubes are tested in compression testing machine with loading rate of 2-4 kN/s. Cubes are loaded perpendicular to casting direction. Maximum load is recorded and strength calculated (load/area). Mean strength of three cubes must meet specified class at 28 days. 7-day strength typically 60-75% of 28-day strength, useful for early verification.

Troubleshooting Low Strength Results

Low mortar strength can result from: incorrect proportions (excess sand), poor quality materials, contamination, inadequate mixing, improper curing, or testing errors. Investigation includes checking batch proportions, cement quality, sand grading, water content, and mixing procedures. Remedial measures may include adjusting mix design, improving quality control, or structural assessment if material already placed.

Conclusion

Mortar strength testing ensures consistent masonry construction quality and specification compliance. Our laboratory performs mortar testing to EN and ASTM standards with proper sampling and curing. Contact us for masonry mortar testing services.

Related Testing Services

- Brick Compression Testing

- Masonry Prism Testing

- Mortar Workability

- Cement Testing

Applicable Standards

Need This Testing Service?

Our accredited laboratories and field teams provide comprehensive testing services across Europe.

Contact Our Team