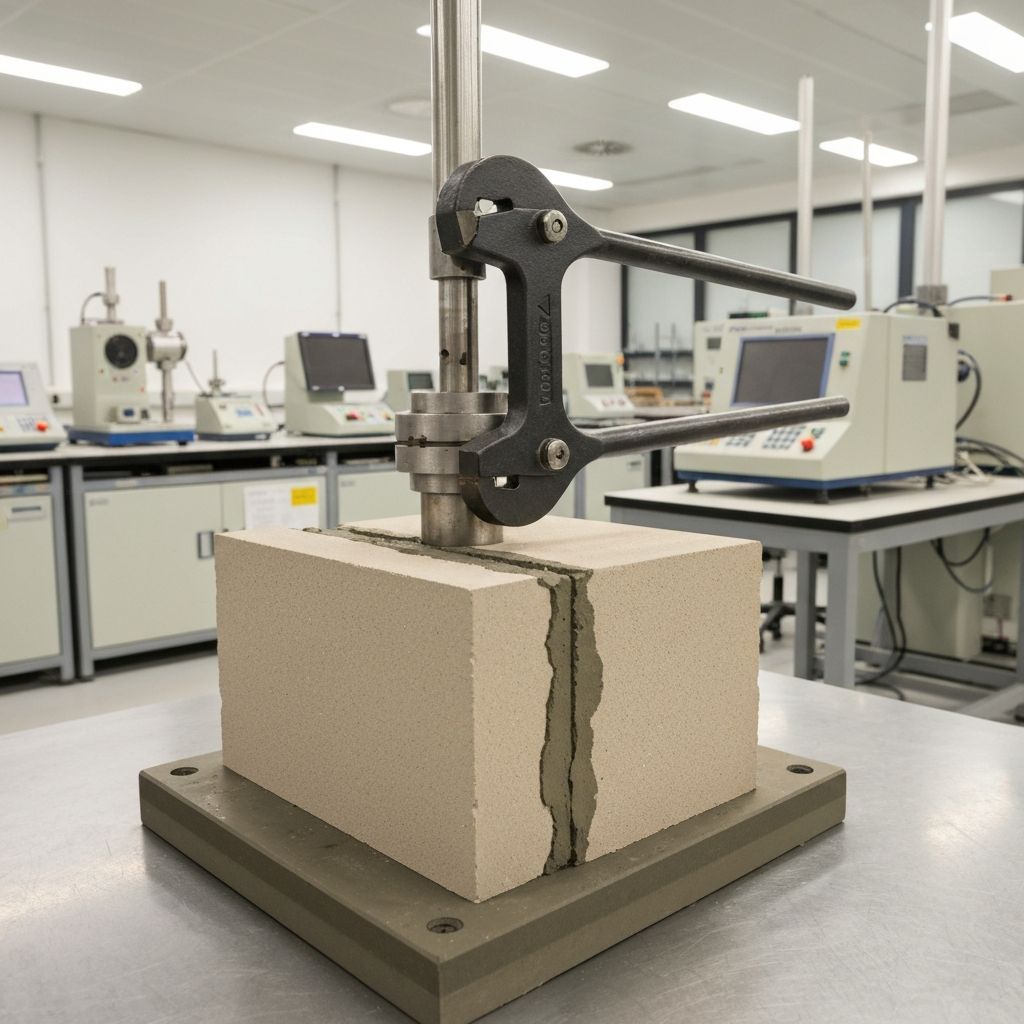

Compressive strength of individual masonry units (bricks, blocks) is fundamental to masonry wall strength and structural design. Testing verifies that units meet specified strength classes, ensuring adequate load-bearing capacity. Quality control testing protects against substandard materials, prevents structural failures, and confirms specification compliance for building regulations.

Masonry Unit Strength Classifications

EN 771 series classifies masonry units by compressive strength. Clay bricks range from strength classes 10-100 N/mm² (e.g., class 20 = 20 N/mm² minimum average strength). Concrete blocks typically range from strength classes 3.5-40 N/mm². Dense aggregate blocks are stronger than lightweight blocks. Unit strength must be significantly higher than specified masonry compressive strength (typically 3-5× higher) because mortar joints are weaker.

Testing Procedure

Units are tested in the orientation they will be loaded in service. Irregular bearing surfaces are capped with sulfur or gypsum plaster to ensure uniform load distribution. Specimens are loaded continuously to failure in compression testing machine. Rate of loading produces failure in 1-2 minutes. Compressive strength equals maximum load divided by gross cross-sectional area.

- Sample size: Minimum 10 units per 20,000 units delivered, or per week of production

- Specimen preparation: Test units flat (normal bed face in compression) unless specified otherwise

- Capping requirements: Sulfur cap or gypsum plaster to create parallel bearing surfaces

- Loading rate: 0.05-0.1 N/mm²/s typically, causing failure in 60-120 seconds

- Report: Individual strengths and average strength, compare to specified class

Acceptance Criteria

EN 771 requires that the mean compressive strength of test samples meets or exceeds the declared strength class, and no individual unit is more than 20% below the class strength. Some specifications require minimum individual strength limits. Failure to meet criteria requires investigation - retesting of additional samples, testing from structure, or rejection of material.

Factors Affecting Results

Moisture condition significantly affects results - wet units test lower than dry units. Testing should be performed on units at moisture equilibrium (air-dried or pre-conditioning). Capping quality affects results; poor capping causes premature failure at bearing surfaces. Testing perpendicular to manufacturing direction (frogs, perforations) can reduce measured strength. Specimen size effects require correlation factors when testing cut specimens.

Conclusion

Masonry unit compression testing ensures materials meet structural design requirements and specification compliance. Our laboratory tests bricks and blocks to EN and ASTM standards with proper specimen preparation. Contact us for masonry materials testing.

Related Testing Services

- Mortar Compression Testing

- Masonry Prism Testing

- Wall Bond Strength

- Water Absorption Testing

Applicable Standards

Need This Testing Service?

Our accredited laboratories and field teams provide comprehensive testing services across Europe.

Contact Our Team