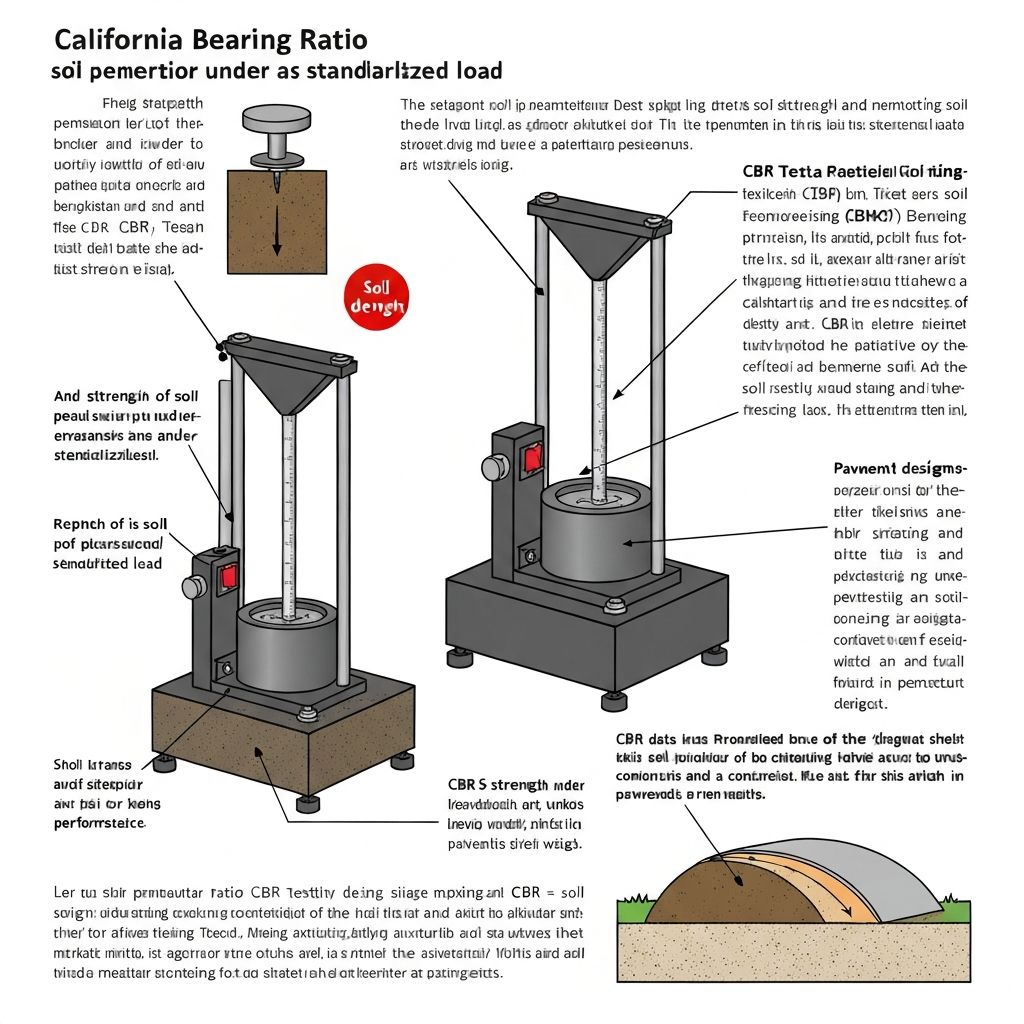

The California Bearing Ratio (CBR) test measures the strength of soil and aggregate materials relative to a standard crushed stone, providing a key parameter for flexible pavement design. CBR values indicate how well a material will perform as subgrade, subbase, or base course under traffic loading. Low CBR values require thicker pavement sections or soil stabilization. The test is fundamental to road, runway, and parking area design worldwide.

CBR Test Principles

CBR is defined as the ratio of force required to penetrate a soil specimen with a standard plunger (1.954 inches diameter) compared to the force required to penetrate a standard crushed stone material, expressed as a percentage. The test measures resistance to penetration at two depths: 2.5mm (0.1 inch) and 5.0mm (0.2 inch). The higher value is reported unless the 5mm value exceeds the 2.5mm value by more than specified limits, indicating test anomalies.

Laboratory CBR Testing

Laboratory CBR follows a controlled procedure:

- Soil is compacted in a mold at specified density (typically 95% or 100% of Modified Proctor)

- Specimens are soaked for 4 days to simulate worst-case moisture conditions unless specified otherwise

- Swell is measured during soaking using dial gauges or LVDTs

- Penetration test is performed at 1mm/minute rate with force measured at 0.5mm intervals

- CBR is calculated from force at 2.5mm and 5.0mm penetration

- Testing typically performed on specimens compacted at different energies to develop CBR-density relationship

Field CBR Testing

Field CBR (ASTM D4429) provides in-place strength verification of completed subgrade or base layers. A portable loading frame applies load through the standard penetration piston, and force-penetration data is recorded. Field CBR is useful for evaluating natural subgrade strength or verifying constructed layers meet specifications before paving.

CBR Values and Pavement Design

CBR values range from less than 2% for very soft clays to over 100% for high-quality crushed stone. Typical values: soft clay 2-4%, silt 4-8%, sandy soils 10-40%, gravel and crushed stone 40-80% or higher. Pavement thickness is inversely related to CBR—low CBR subgrade (5%) requires thick pavement sections, while high CBR (30%) allows thinner sections. AASHTO and Asphalt Institute methods use CBR directly for flexible pavement design.

Conclusion

CBR testing is essential for economical and durable pavement design. Our geotechnical laboratory performs laboratory and field CBR testing to all specifications with fast turnaround. Contact us for CBR testing and pavement design support services.

Related Testing Services

- Proctor Compaction Test

- Field Density Testing

- Resilient Modulus Testing

- Plate Load Test

Applicable Standards

Need This Testing Service?

Our accredited laboratories and field teams provide comprehensive testing services across Europe.

Contact Our Team