The Proctor compaction test is the fundamental laboratory test used to establish the maximum dry density and optimum moisture content relationship for soils. These laboratory values serve as the reference standard for field compaction control. The test simulates field compaction by applying controlled compaction energy to soil at various moisture contents, producing a compaction curve that defines the maximum achievable density.

Standard vs. Modified Proctor

Two versions of the test apply different compaction energies:

- Standard Proctor (ASTM D698, EN 13286-2): 5.5 lb hammer, 12-inch drop, 25 blows per layer, 3 layers. Energy: 12,400 ft-lb/ft³. Simulates light compaction equipment.

- Modified Proctor (ASTM D1557): 10 lb hammer, 18-inch drop, 25 blows per layer, 5 layers. Energy: 56,000 ft-lb/ft³. Simulates heavy compaction equipment and is standard for roadway applications.

- Modified Proctor yields 5-10% higher maximum density than Standard Proctor for the same soil

Test Procedure

Soil samples are prepared at varying moisture contents spanning dry to wet of optimum. Each sample is compacted in a standardized mold following the specified procedure. After compaction, the moist density and moisture content are determined. Dry density is calculated by dividing moist density by (1 + moisture content). The compaction curve is plotted (moisture vs. dry density), and maximum dry density and optimum moisture content are determined from the peak.

Interpreting the Compaction Curve

The compaction curve shows dry density increasing with moisture content (dry side) up to an optimum point, then decreasing (wet side) as water displaces soil particles. Coarse-grained soils (sands, gravels) have flat curves with low moisture sensitivity. Fine-grained soils (clays) have sharp peaks and are very moisture-sensitive. The zero air voids curve represents theoretical maximum density with no air voids.

Field Application

Field compaction specifications reference the laboratory maximum dry density (e.g., 'compact to 95% of Modified Proctor maximum dry density'). Optimum moisture content guides field moisture control—soil compacted dry of optimum is stiff and difficult to achieve density; wet of optimum is soft and unstable. Field moisture is adjusted with water trucks or aeration to achieve compaction within 2% of optimum.

Conclusion

Proctor testing is the foundation of earthwork quality control, establishing the density and moisture benchmarks for field verification. Our geotechnical laboratory performs both Standard and Modified Proctor testing to ASTM and EN standards. Contact us for comprehensive soil testing services.

Related Testing Services

- Field Density Testing

- Moisture-Density Relationship

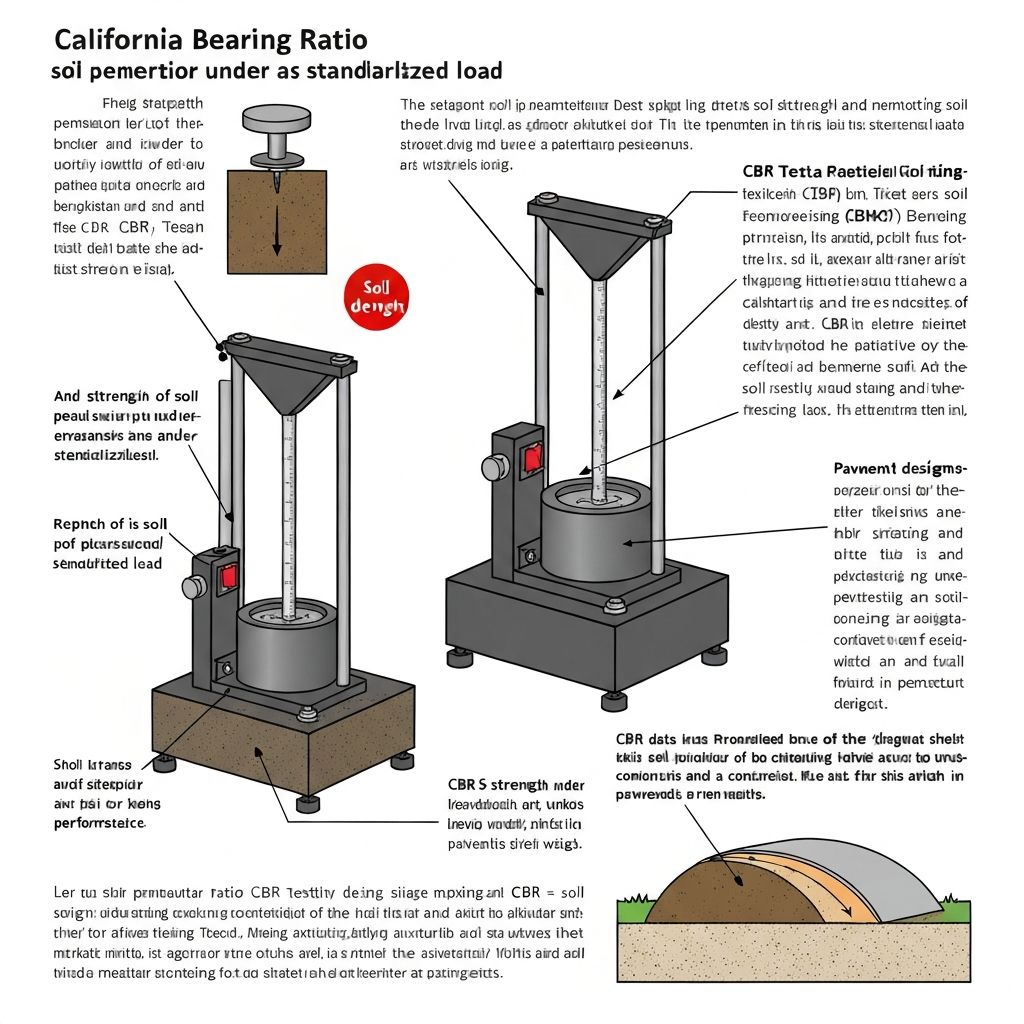

- CBR Testing

- Grain Size Analysis

Applicable Standards

Need This Testing Service?

Our accredited laboratories and field teams provide comprehensive testing services across Europe.

Contact Our Team