Chloride penetration testing measures concrete's resistance to chloride ion ingress, the primary cause of reinforcement corrosion in marine environments and structures exposed to de-icing salts. Chloride-induced corrosion is the most costly durability problem in concrete infrastructure, affecting bridges, parking structures, and coastal buildings throughout Europe.

Understanding Chloride-Induced Corrosion

Steel reinforcement is naturally protected by concrete's alkaline environment (pH 12-13), which creates a passive oxide layer. Chloride ions break down this passivation, initiating corrosion even in alkaline conditions. Once started, corrosion products expand up to 6 times the volume of steel, generating internal pressures that crack and spall concrete. Testing ensures concrete provides adequate barrier protection.

Testing Methods

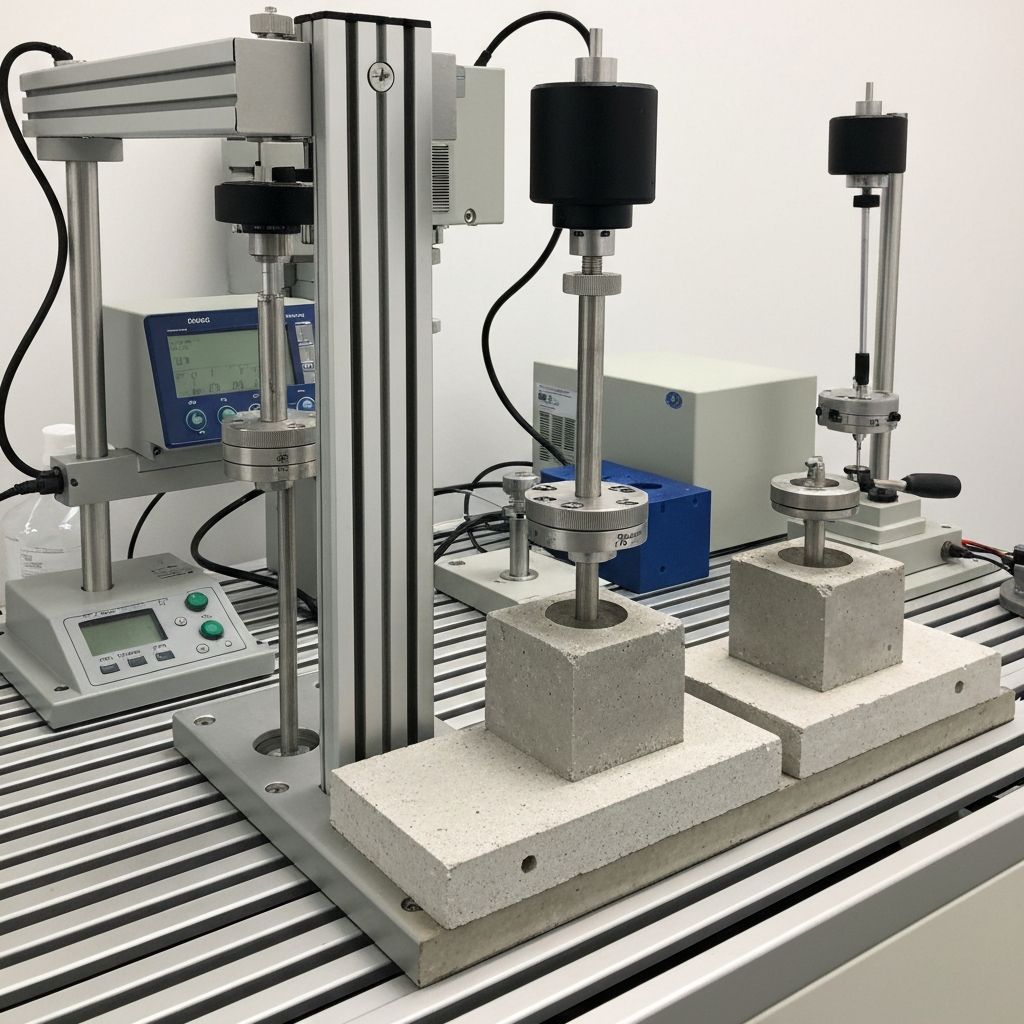

Multiple methods assess chloride resistance with varying complexity and duration:

- Rapid Chloride Migration (RCM) Test (NT BUILD 492): Electric field accelerates chloride migration, results in 24 hours

- Rapid Chloride Permeability Test (ASTM C1202): Measures electrical conductance as indicator of ion permeability

- Bulk Diffusion Test (NT BUILD 443): Long-term exposure (3-6 months) for diffusion coefficient

- Chloride Content Analysis (EN 14629): Chemical analysis of chloride already in concrete

Interpreting Results and Specifications

EN 206 classifies concrete exposure classes (XD, XS) with corresponding chloride penetration resistance requirements. Very low permeability (<1000 coulombs ASTM C1202) is required for severe marine exposure. Migration coefficients below 8×10⁻¹² m²/s indicate excellent chloride resistance. Specifications often combine water-cement ratio limits, minimum cement content, and supplementary cementitious materials to achieve required performance.

Improving Chloride Resistance

Low water-cement ratio (≤0.40) is fundamental. Silica fume, fly ash, and slag significantly improve chloride resistance by refining pore structure. Adequate concrete cover (50-75mm for severe exposure) provides depth of protection. Proper curing is essential - even low permeability concrete requires adequate curing to develop chloride resistance. Surface treatments and protective coatings provide additional barriers.

Conclusion

Chloride penetration testing is critical for long-term durability of reinforced concrete in aggressive environments. Our laboratory performs rapid migration testing and chloride analysis to European standards. Contact us for comprehensive corrosion protection testing.

Related Testing Services

- Half-Cell Potential Testing

- Water Permeability Testing

- Carbonation Depth

- Concrete Cover Measurement

Applicable Standards

Need This Testing Service?

Our accredited laboratories and field teams provide comprehensive testing services across Europe.

Contact Our Team