Penetration and softening point are the two fundamental tests for bitumen grading and quality control. Penetration measures consistency (hardness) at 25°C, classifying bitumen into grades like 40/60, 70/100, or 160/220. Softening point measures the temperature at which bitumen reaches a specific viscosity. Together, these tests ensure bitumen meets grade specifications and predict pavement performance across temperature ranges.

Penetration Test Method

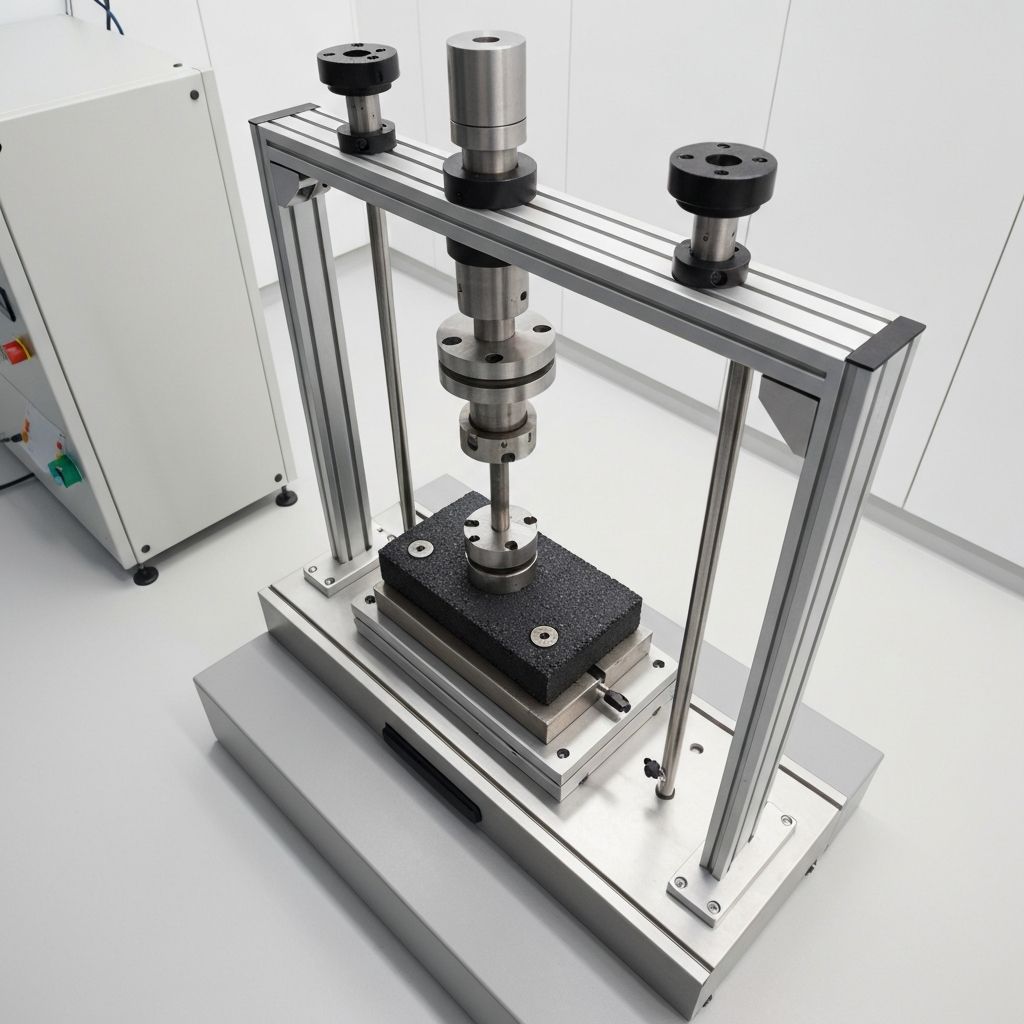

The penetration test (EN 1426, ASTM D5) measures the depth a standard needle penetrates bitumen under specific conditions. A 100g needle loaded for 5 seconds at 25°C penetrates the bitumen sample. Penetration is expressed in tenths of millimeters (0.1mm units called 'dmm'). Harder bitumens (used in hot climates) have low penetration (40-60 dmm). Softer bitumens (cold climates) have high penetration (160-220 dmm). The most common grade worldwide is 50/70.

- Sample conditioning: 25.0°C ± 0.1°C for 1 hour

- Needle load: 100g including needle weight

- Loading time: 5 seconds

- Result: Depth of penetration in 0.1mm units

- Precision: Repeatability ±2 dmm for 50/70 grade

Softening Point (Ring & Ball) Test

The Ring & Ball test (EN 1427, ASTM D36) determines the temperature at which bitumen softens sufficiently that a steel ball, resting on bitumen in a brass ring, sinks 25mm. The apparatus is immersed in water (or glycerin for high-softening bitumens) heated at 5°C/min. The softening point indicates high-temperature performance. High softening point (55-65°C) indicates stiffer bitumen suitable for hot climates. Low values (<45°C) are for cold climates.

Penetration Index and Temperature Susceptibility

The penetration index (PI) calculated from penetration and softening point indicates temperature susceptibility. PI = [1952 - 500×log(Pen) - 20×SP] / [50×log(Pen) - SP]. Values range from -2 (highly temperature susceptible) to +2 (less susceptible). Polymer-modified bitumens show higher PI, indicating better performance across temperature ranges. Conventional bitumen typically has PI between -1 and +1.

Quality Control Applications

Penetration and softening point testing verify bitumen grade from suppliers, confirm grade consistency during production, detect contamination or degradation, and ensure compatibility with mix design. Testing is performed on each bitumen delivery, typically 1-2 tests per 100-200 tonnes. Results must fall within grade limits (e.g., 50-70 dmm penetration, 46-54°C softening point for 50/70 grade). Out-of-specification material is rejected or reclassified.

Conclusion

Penetration and softening point testing are fundamental to bitumen quality control and grade verification. Our accredited laboratory performs these tests daily with high-precision equipment and temperature control. Contact us for bitumen testing and characterization services.

Related Testing Services

- Viscosity Testing

- Ductility Testing

- Fraass Breaking Point

- Rolling Thin Film Oven Test

Applicable Standards

Need This Testing Service?

Our accredited laboratories and field teams provide comprehensive testing services across Europe.

Contact Our Team