The Marshall stability and flow test is the most widely used method for asphalt concrete mix design and quality control. It measures the resistance of asphalt mix to deformation under load (stability) and the amount of deformation (flow). These parameters help optimize binder content, ensure adequate resistance to rutting, and verify mix quality during production and construction.

Test Principle and Significance

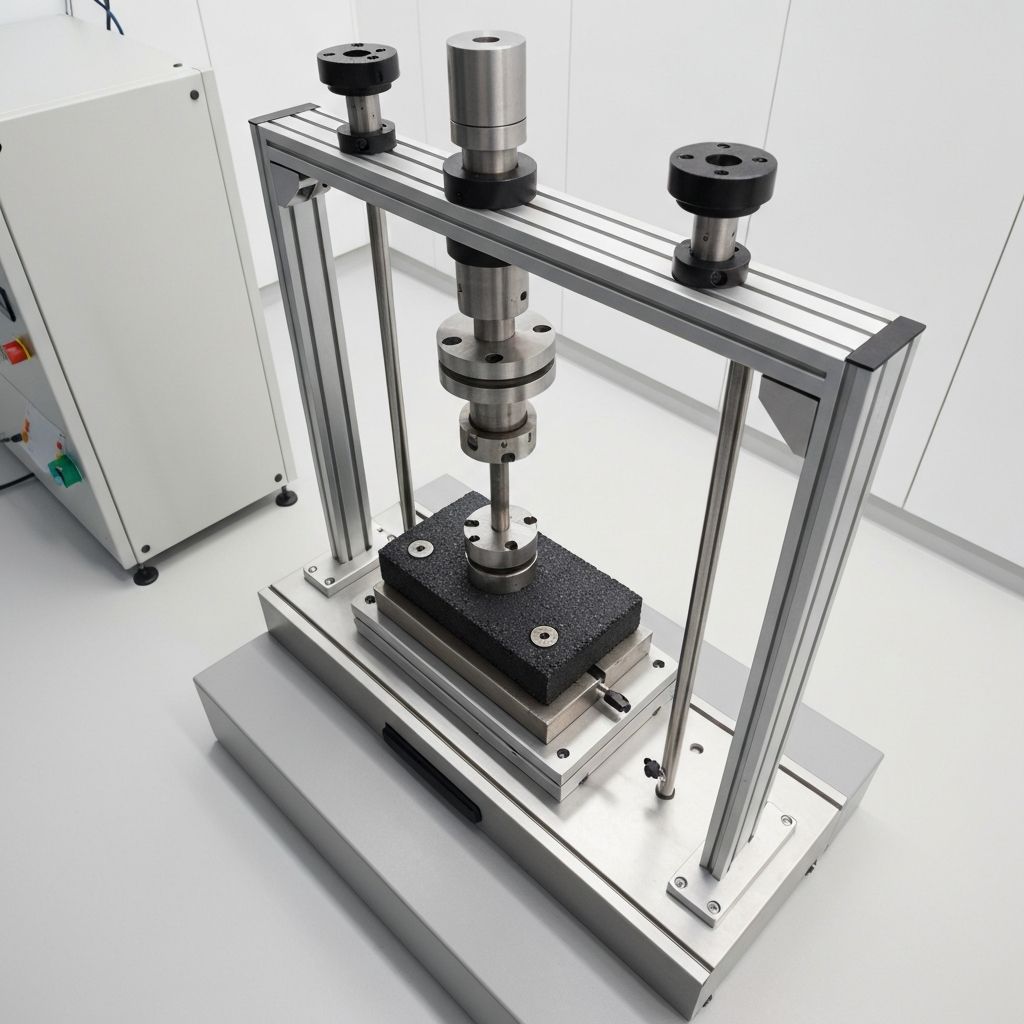

Marshall stability indicates the maximum load that a cylindrical asphalt specimen can withstand before failure when loaded diametrically. Flow is the vertical deformation at maximum load. High stability suggests good resistance to deformation and rutting. Moderate flow indicates sufficient flexibility. The balance between stability and flow indicates a durable, workable mix. The test simulates traffic loading and helps predict pavement performance.

Specimen Preparation and Testing

Standard Marshall specimens are 102mm diameter × 64mm height, compacted with 50 or 75 blows per side using a Marshall hammer (4.5kg dropped from 457mm). Specimens are conditioned in a 60°C water bath for 30-40 minutes before testing. The specimen is placed in a Marshall loading frame and loaded at 50mm/min until failure. Maximum load (stability in kN) and deformation at maximum load (flow in mm) are recorded.

- Compaction: 50 blows for light traffic, 75 blows for heavy traffic

- Conditioning: 60°C water bath, 30-40 minutes

- Loading rate: 50mm/min (constant deformation)

- Typical stability: 8-18 kN depending on mix and traffic

- Typical flow: 2-4 mm, indicates flexibility

Mix Design Optimization

Mix design involves preparing specimens at five bitumen contents (typically 4.0%, 4.5%, 5.0%, 5.5%, 6.0%) and plotting stability, flow, air voids, VMA, and VFA versus bitumen content. The optimum bitumen content is selected based on: target 4% air voids, minimum stability (usually >8 kN), flow within range (2-4mm), and adequate VMA. European mix design increasingly uses performance tests alongside Marshall.

Quality Control and Acceptance

During asphalt production, Marshall specimens are prepared from plant mix or cores from freshly laid pavement. Results are compared with job mix formula (JMF) tolerances. Low stability indicates insufficient binder, poor aggregate quality, or temperature problems. High flow suggests excess binder or contamination. Systematic variations require mix adjustments. Testing frequency is typically one per 1000-2000 tonnes of production.

Conclusion

Marshall testing remains the foundation of asphalt mix design and quality control worldwide. Our accredited laboratory performs Marshall testing and comprehensive asphalt mix design services per European and international standards. Contact us for asphalt testing and mix optimization.

Related Testing Services

- Bulk Density and Air Voids

- Bitumen Content Testing

- Wheel Tracking Test

- Indirect Tensile Strength

Applicable Standards

Need This Testing Service?

Our accredited laboratories and field teams provide comprehensive testing services across Europe.

Contact Our Team