Waterproofing membrane testing ensures roofing and below-grade membranes meet performance requirements for water resistance, mechanical strength, flexibility, and durability. Membrane failure leads to water ingress, structural damage, and costly remediation. Comprehensive testing programs verify membrane properties before installation and during quality control to ensure long-term waterproofing performance.

Critical Membrane Properties

Key properties that determine membrane performance include: tensile strength and elongation (ability to withstand installation stresses and building movement), tear resistance (resistance to damage during installation), puncture resistance (withstanding roof traffic and sharp objects), water absorption (minimal absorption prevents degradation), and weathering resistance (UV, heat, cold, ozone exposure).

Tensile Testing and Elongation

Tensile testing measures membrane strength and flexibility by pulling specimens to failure. Samples are cut in machine and cross directions, conditioned at standard temperature, and tested at specified grip separation and loading rate. Both maximum force (tensile strength) and elongation at break are recorded. Bituminous membranes typically require >500N/50mm tensile strength and >5% elongation. Single-ply membranes require >800N/50mm and >200% elongation depending on type.

- Test standards: EN 12311-1 (flexible sheets), EN 12311-2 (bituminous)

- Specimen width: 50mm, length: 200mm

- Test speed: 50mm/min for flexible sheets, 25mm/min for bituminous

- Conditioning: 23°C ± 2°C, 50% ± 5% RH for 24 hours minimum

- Report: Maximum force (N/50mm), elongation at break (%)

Water Absorption and Permeability

Water absorption testing measures the membrane's resistance to moisture uptake, which can lead to degradation and loss of properties. Specimens are immersed in water for specified periods (typically 24 hours) and the weight gain measured. Low absorption (<1% for bituminous, <3% for some synthetic membranes) indicates good resistance. Permeability testing measures water vapor transmission rate, important for roof system design.

Additional Testing Requirements

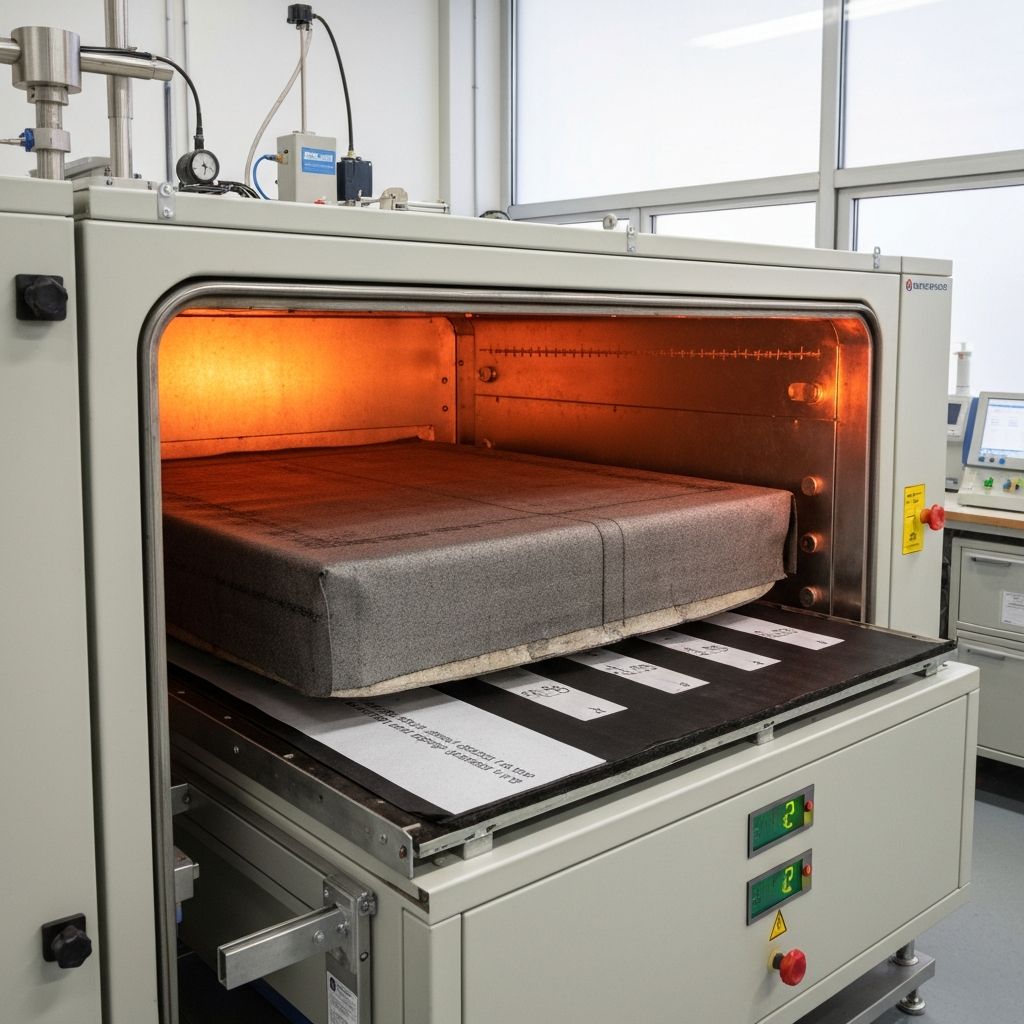

Comprehensive membrane evaluation includes: tear resistance (trapezoidal tear test per EN 12310), puncture resistance (static and dynamic loads), peel/seam strength (for laminated membranes), flexibility at low temperature (cold bend test), heat aging (accelerated aging to simulate long-term exposure), and weather resistance (artificial UV and heat cycling). Testing programs are specified per EN 13416 (bituminous) or EN 13707 (PVC).

Conclusion

Comprehensive membrane testing ensures waterproofing systems provide reliable long-term protection. Our laboratory performs complete testing programs for roofing and waterproofing membranes to European standards. Contact us for membrane qualification and quality assurance testing.

Related Testing Services

- Seam Strength Testing

- Weather Resistance Testing

- Cold Flexibility Testing

- Heat Aging Testing

Applicable Standards

Need This Testing Service?

Our accredited laboratories and field teams provide comprehensive testing services across Europe.

Contact Our Team