Bituminous membranes are subject to harsh environmental conditions including UV radiation, extreme temperatures, and thermal cycling. Heat aging and weather resistance testing simulates long-term exposure to predict membrane performance over decades of service. These accelerated tests identify membranes that will maintain flexibility, strength, and waterproofing properties throughout their design life.

Why Aging Testing is Critical

Bitumen degrades through oxidation when exposed to heat and UV radiation, becoming brittle and prone to cracking. In roof applications, surface temperatures can exceed 70-80°C in summer. Repeated heating and cooling cycles cause expansion and contraction. Over time, these factors cause hardening, loss of flexibility, and eventual failure. Accelerated aging testing predicts long-term performance from short-term laboratory exposure.

Heat Aging Test Procedure

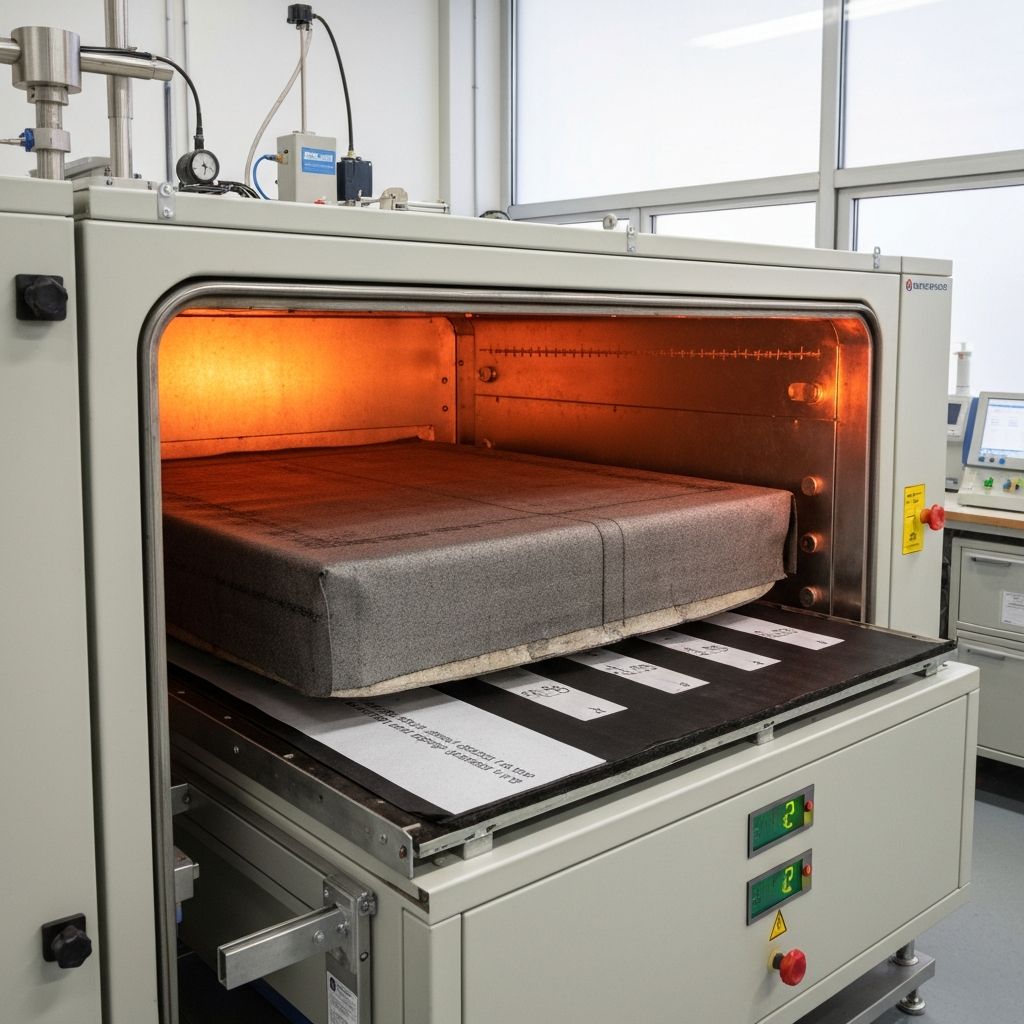

Membrane specimens are exposed to elevated temperature in a forced-air oven for specified periods. EN 1296 requires conditioning at 70°C for 168 hours (7 days) or 28 days for oxidized bitumen membranes. After aging, specimens are tested for tensile properties, flexibility, and visual appearance. Excessive loss of elongation or cracking indicates poor aging resistance. Modified bitumen membranes with SBS or APP polymers show superior aging resistance compared to oxidized bitumen.

- Test temperature: 70°C ± 2°C in ventilated oven

- Duration: 168 hours or 28 days depending on membrane type

- Post-aging tests: Tensile strength, elongation, flexibility

- Acceptance: <20% loss in tensile properties, no cracking

- Advanced testing: ASTM D5147 (peel strength retention)

Artificial Weathering Testing

Artificial weathering (EN 1297) subjects membranes to cyclic exposure simulating sun, heat, and moisture. Testing uses xenon arc or UV fluorescent lamps combined with water spray and thermal cycling. Exposure duration ranges from 1000-5000 hours equivalent to years of natural exposure. Surface changes, color stability, tensile properties, and flexibility are evaluated. Membranes with UV-stable surfacing (granules, foils) show better weather resistance.

Thermal Cycling and Low Temperature Flexibility

Thermal cycling tests repeated heating and cooling (e.g., -30°C to +80°C cycles) to simulate seasonal variations. Low temperature flexibility testing (EN 1109) measures the lowest temperature at which membranes remain flexible. Specimens are bent over a mandrel at decreasing temperatures until cracking occurs. Good membranes remain flexible to -25°C or lower. This property is critical for cold climates where brittle fracture can occur.

Conclusion

Accelerated aging and weather resistance testing ensures bituminous membranes will perform throughout their intended service life. Our laboratory provides comprehensive durability testing programs per European standards. Contact us for membrane aging and weathering assessment.

Related Testing Services

- Tensile Testing

- Cold Flexibility Testing

- Dimensional Stability

- Natural Weathering Exposure

Applicable Standards

Need This Testing Service?

Our accredited laboratories and field teams provide comprehensive testing services across Europe.

Contact Our Team